Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

Address

No. 128, Binhe Road, Gongyi City

Zhengzhou City, Henan Province, China, 451200

Contact us

Phone: (+86) 13386837400

WhatsApp/WeChat: (+86) 13386837400

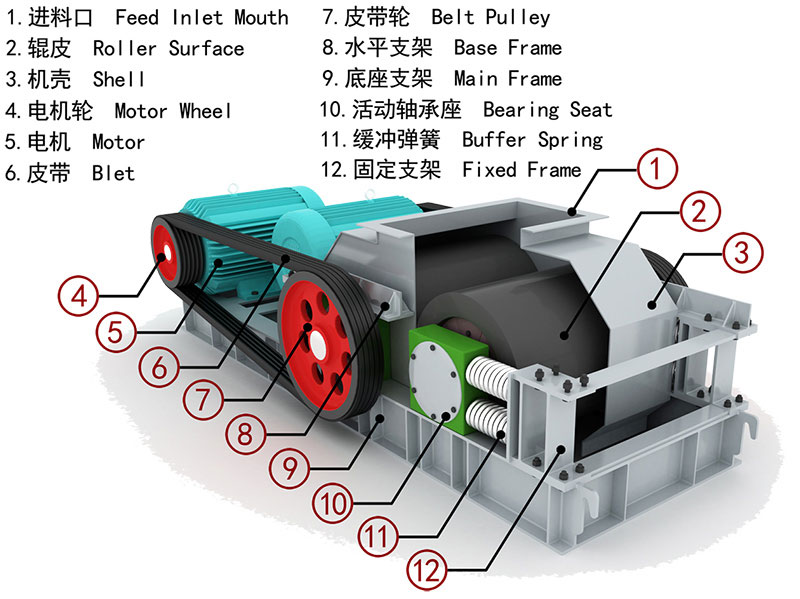

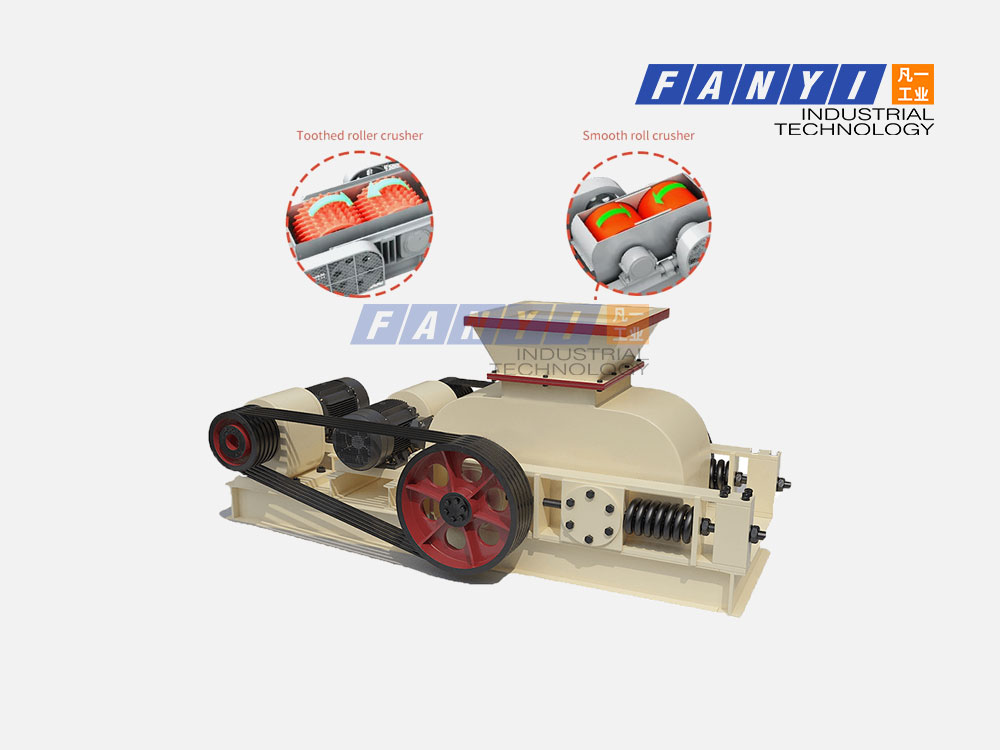

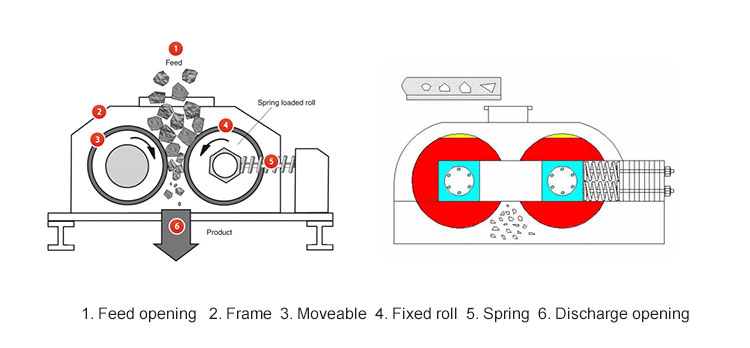

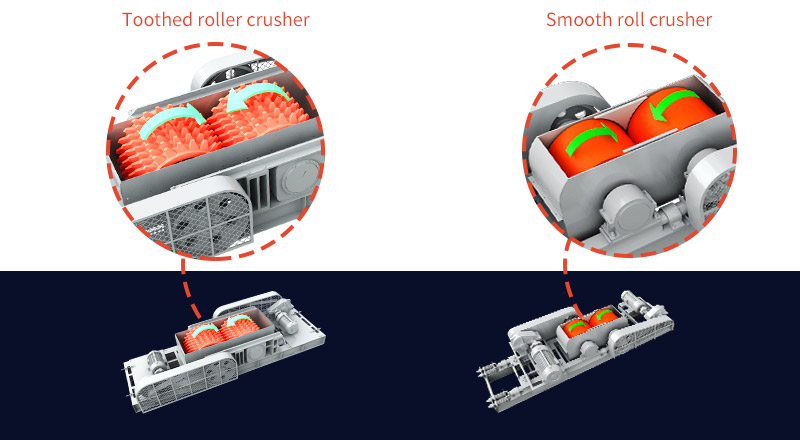

OEM Mine Crusher Parts, Double Roller Crusher Roller Shell, Smooth Roll Crusher, Toothed Roller Crusher, Roller Skin, Wear&Spare parts

Strict Casting Standards & advanced manufacturing processes.

Our products smooth surface, accurate dimensions and weight, high hardness, high wear resistance and longer life.

Fast Delivery – Large inventory of consumable parts for regular models of jaw crusher/cone crusher/roller crusher to ensure reliable delivery.

Focus on designs and manufacturing replacement wear parts for roll crushers. Our engineers get to know your specific needs through consultation with you and customize a best-fit solution for your application.

Roll crusher wear parts are cast with proprietary alloys for maximum wear life in high abrasive environments. It is our mission to provide you with wear parts that deliver longest wear life and improve the overall efficiency of your roll crusher.

|

Specification and model

|

Roll diameter

(mm) |

Feed size

(mm) |

Productive capacity

(t/h) |

|

2PGT400×250

|

φ400

|

≤25

|

2-10

|

|

2PGT400×400

|

φ400

|

≤25

|

5-12

|

|

2PGT610×400

|

φ610

|

≤30

|

5-20

|

|

2PGT750×500

|

φ750

|

≤30

|

10-40

|

|

2PGT800×600

|

φ800

|

≤40

|

12-50

|

|

2PGY800×800

|

φ800

|

≤40

|

40-50

|

|

2PGY800×1000

|

φ800

|

≤40

|

50-80

|

|

2PGY1000×800

|

φ1000

|

≤40

|

50-80

|

|

2PGY1000×1000

|

φ1000

|

≤40

|

80-100

|

|

2PGY1200×1000

|

φ1200

|

≤60

|

100-120

|

|

2PGY1200×1200

|

φ1200

|

≤60

|

120-150

|

|

2PGY1500×1000

|

φ1500

|

≤80

|

150-200

|

|

2PGY1500×1200

|

φ1500

|

≤80

|

200-250

|

|

2PGY1800×1000

|

φ1800

|

≤100

|

250-300

|

|

2PGY2000×1200

|

φ2000

|

≤120

|

300-400

|